Products

Product/technological information

12. Preload

Preload may be applied when a high dynamic rotational accuracy is required of the bearing, and when low vibration and noise, and a high impact resistance are required. Preload can be applied by inserting a spring, shim, or spacer, or by grinding the face of the outer or inner ring to achieve the desirable preload of the two bearings.

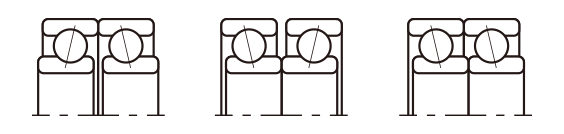

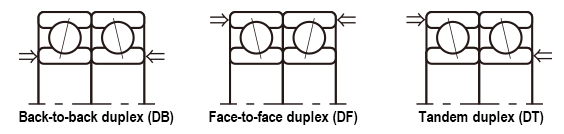

(1) Back-to-back duplex (DB)

- As the line of action faces outward, a high moment load resistance is achieved.

- As the positioning in the radial and axial directions are accurate, the displacement may be controlled easily.

(2) Face-to-face duplex (DF)

- As the line of action faces inward, the moment load resistance becomes smaller than the DB duplex, but the shaft inclination can be absorbed easily.

- As the positioning in the radial and axial directions are accurate, the displacement may be controlled easily.

(3) Tandem duplex (DT)

- This is used to increase the load capacity and rigidity. However, as the tandem duplex can receive radial load and unidirectional axial load only, the axial load in the opposite direction must be received by using another bearing.

Before mounting

After mounting

Preload(reference)

| Preload category | Preload | Features | |

|---|---|---|---|

| Miniature and small bearing | Standard bearing | ||

| Slight preload (S) | 0.50%×Cr | 0.15%×Cr | Bearing rigidity not required, emphasis on low torque |

| Light preload (L) | 1.25%×Cr | 0.58%×Cr | Bearing rigidity and low torque are both required |

| Medium preload (M) | 1.75%×Cr | 1.28%×Cr | Emphasis on bearing rigidity, relatively high torque |

| Heavy preload (H) | 2.50%×Cr | 2.64%×Cr | Emphasis on bearing rigidity, high torque |

※ Cr = Basic dynamic load rating (N)

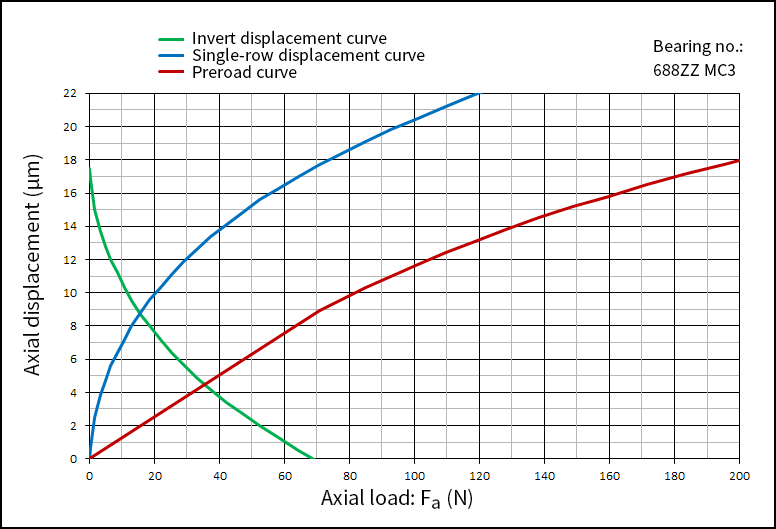

Axial load and axial displacement of duplex bearings